Brushless DC motor, brush DC motor: How to choose?

Share

Brushless DC motor (BLDC) is a kind of permanent magnet synchronous motor, not a real DC motor, BLDC for short, which is different from brushed DC motor, brushless DC motor does not use mechanical brush device, using square wave self-control permanent magnet synchronous motor, using Hall sensor instead of carbon brush commutator, using neodymium iron boron as the permanent magnet material of rotor, the performance has a great advantage compared with the general traditional DC motor. It is the most ideal motor for speed control today.

I. Introduction of Brush DC Motor

Before introducing brushless DC motors, let's take a look at brushed motors.

DC motor is known for its good starting performance, speed control performance and other advantages, which belongs to a class of DC motor brush DC motor using mechanical commutator, making the drive method simple, its model schematic diagram is shown below.

DC motor (brush motor) operation diagram

The motor is mainly composed of a stator made of permanent magnet material, a rotor (armature) with coil windings, commutator and brushes. The commutator of the motor automatically changes the direction of the magnetic field of the motor rotor as long as a certain DC current is applied to the A and B ends of the brushes, so that the rotor of the DC motor will continue to run.

DC motors have the following disadvantages

Relatively complex structure, which increases the manufacturing cost.

being easily affected by the environment (e.g. dust, etc.), which reduces the reliability of operation.

generating sparks during commutation, limiting the range of use

Easily damaged, increasing maintenance costs, etc.

Introduction of brushless DC motor

The "BL" in BLDC motor means "brushless", which means that the "brush" in DC motor (brush motor) is not available.

Brushless DC motor (BLDC) replaces the mechanical commutator with electronic commutator, so the brushless DC motor has the characteristics of good speed control performance of DC motor, but also has the advantages of simple structure of AC motor, no commutation spark, reliable operation and easy maintenance.

Brushless DC motors consist mainly of a rotor made of permanent magnet material, a stator with coil windings and a position sensor (optional). As can be seen, it has a lot in common with the DC motor, the stator and rotor have a similar structure (the original stator becomes the rotor and the rotor becomes the stator), and the winding connections are basically the same. However, there is one obvious difference in their structures: brushless DC motors do not have commutators and brushes as in DC motors, but position sensors instead. This makes the motor structure relatively simple and reduces the manufacturing and maintenance cost of the motor, but the brushless DC motor cannot change direction (phase) automatically, at the expense of the motor controller cost (e.g. the same three-phase DC motor, the drive bridge of the brush DC motor requires 4 power tubes, while the drive bridge of the brushless DC motor requires 6 power tubes).

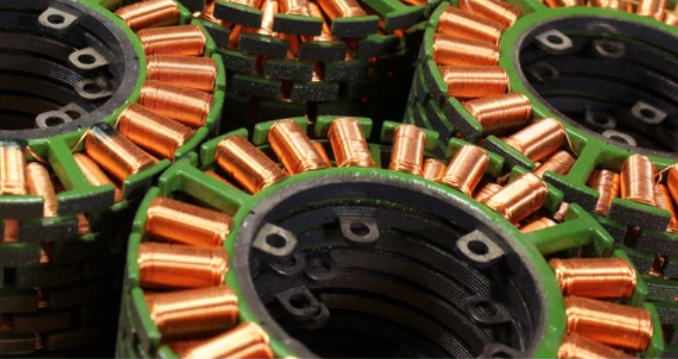

The figure above shows one of the small power three-phase, star-connected, single-pair magnetic brushless DC motors, which has the stator inside and the rotor outside. Another type of brushless DC motor is just the opposite, with the stator outside and the rotor inside, i.e., the stator is a coil winding consisting of the chassis, while the rotor is made of permanent magnet material.

Brushless DC motors have the following characteristics

good external characteristics of the brushless DC motor, which enables it to deliver large torque at low speeds, making it possible to provide large starting torque.

the wide speed range of the brushless DC motor, allowing it to operate at full power at any speed.

the high efficiency and overload capability of the brushless DC motor, making it an excellent performer in drag systems.

the good regenerative braking effect of the brushless DC motor, which allows the motor to enter the generator state during braking due to its permanent magnet material rotor.

the small size and high power density of brushless DC motors.

the brushless DC motor has no mechanical commutator and adopts a fully enclosed structure, which can prevent dust from entering the inside of the motor and is highly reliable.

Brushless DC motors are simpler to drive and control than asynchronous motors.

So, why not buy handheld electric fans made up of brushless motors from HandFan.com? We offer handheld fans for different usage scenarios to meet your daily needs.